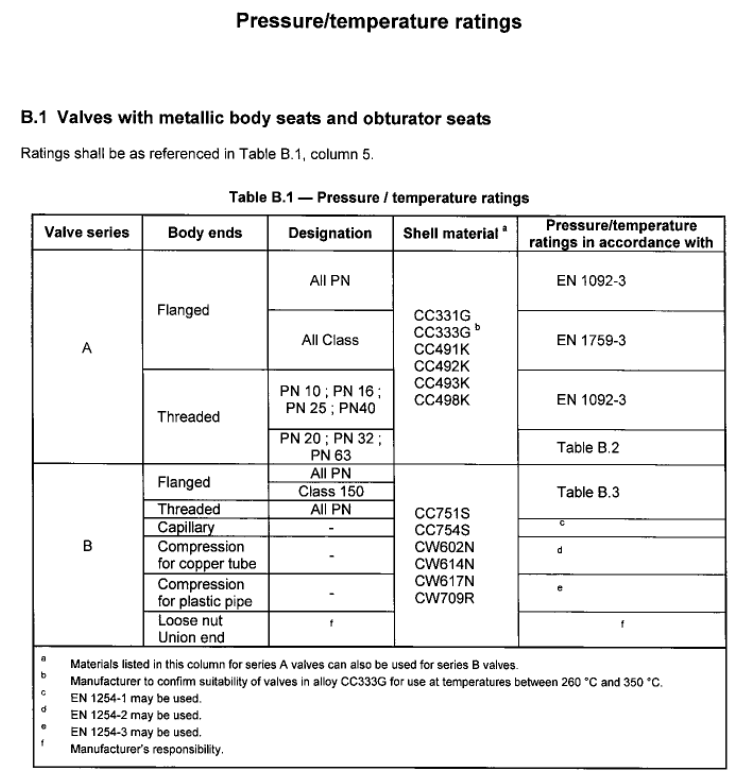

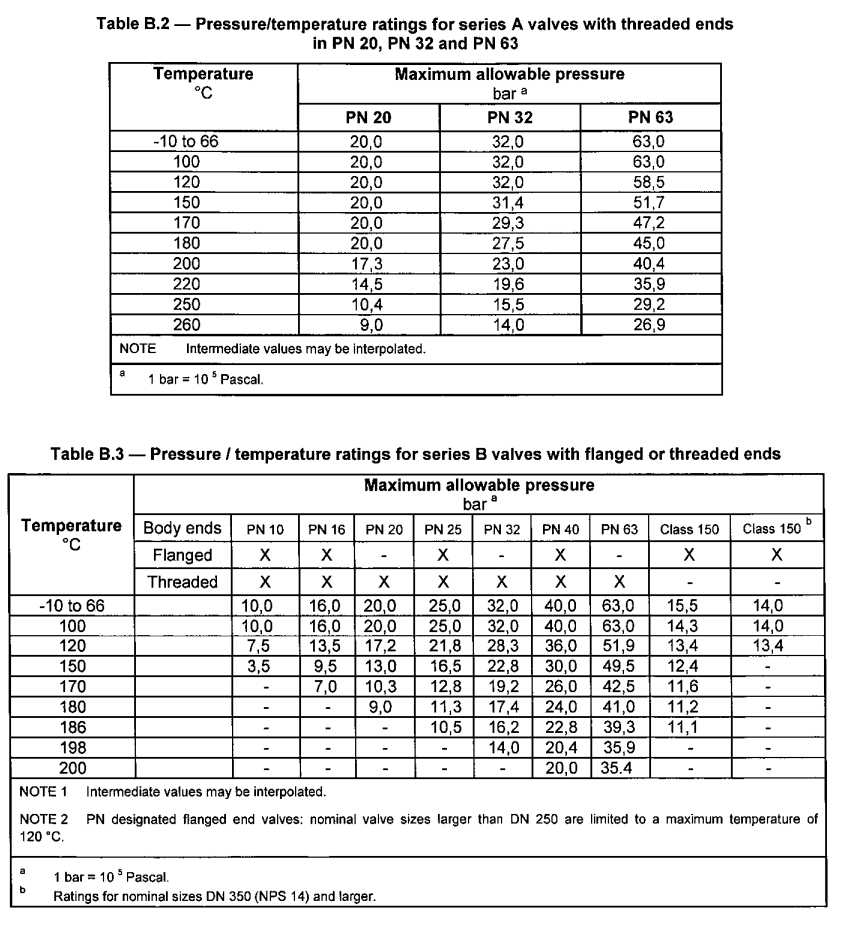

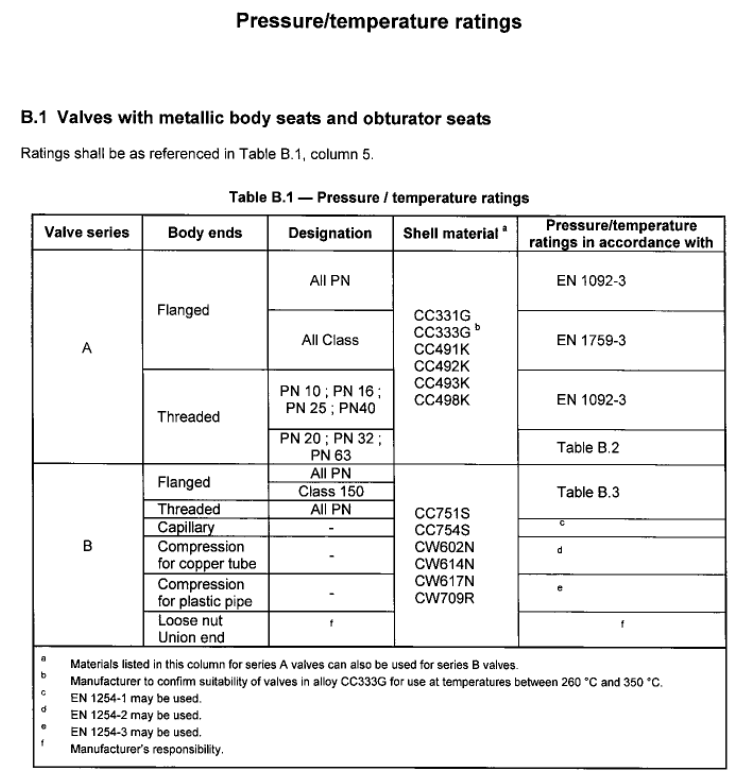

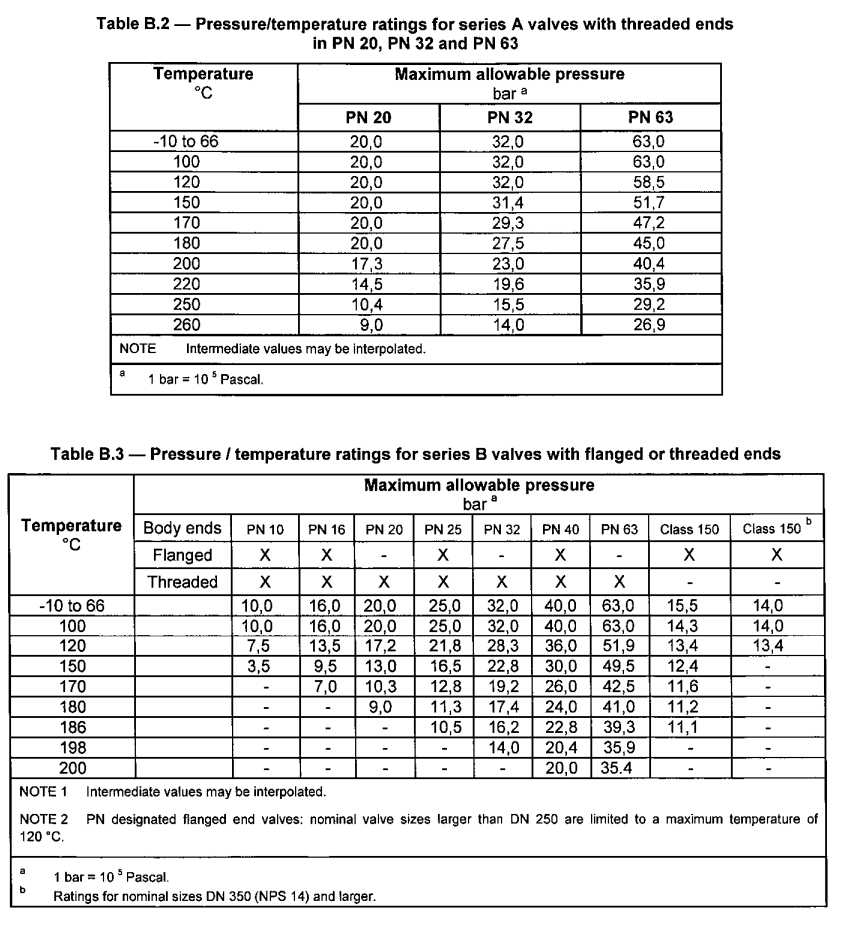

A. Pressure – Temperature rating

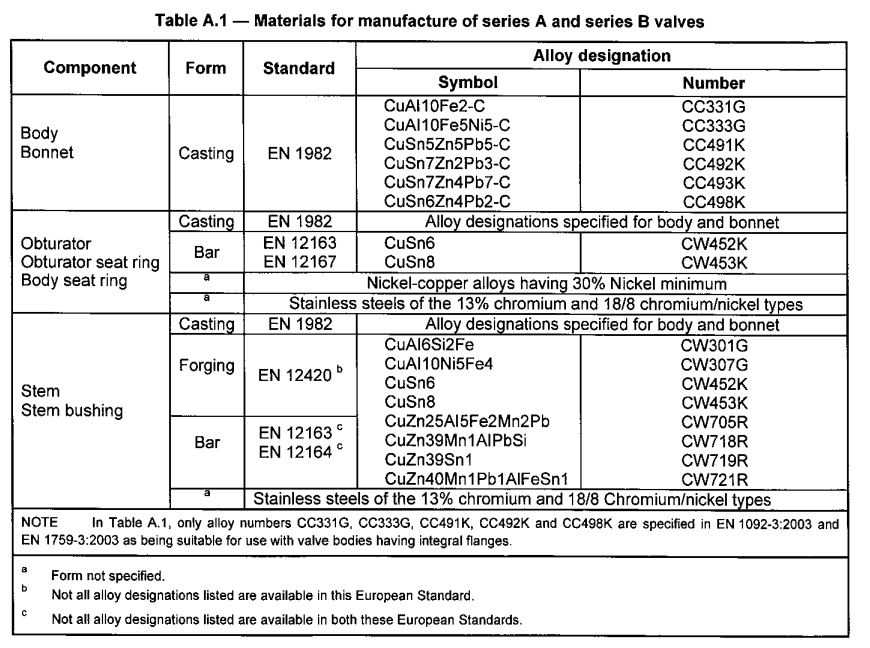

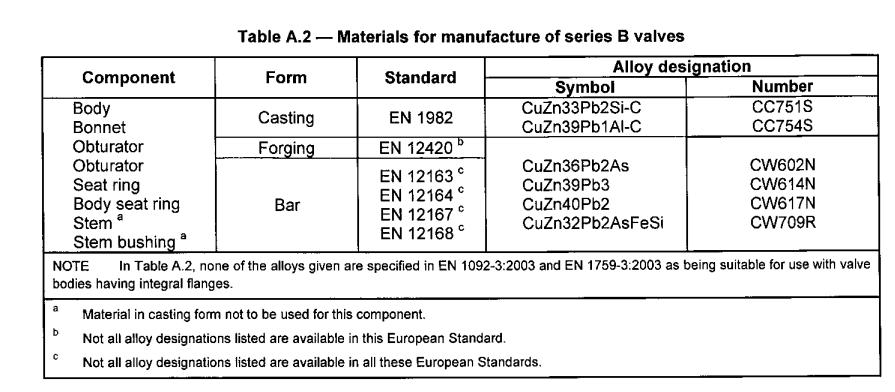

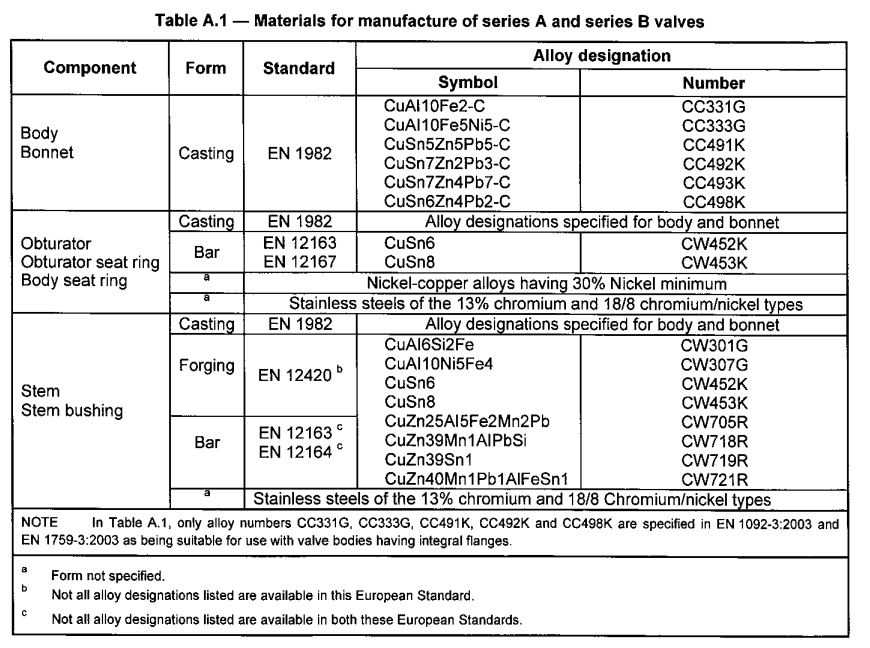

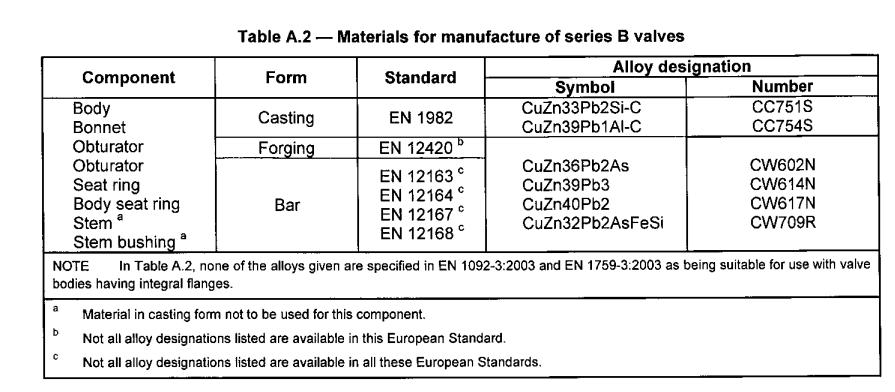

B. Material covered under BS EN 12288

A. Pressure – Temperature rating

B. Material covered under BS EN 12288

Any water fitting, which when installed, will carry or receive water from the public mains water supply in the UK, must comply with the Water Supply (Water Fittings) Regulations or Scottish Byelaws. These require that a water fitting should not cause waste, misuse, undue consumption or contamination of the water supply and must be ‘of an appropriate quality and standard’.

WRAS Approval is the easiest way to demonstrate compliance as it is granted directly by representatives of the water suppliers and is therefore accepted by every water supplier in the UK.

WRAS Product Approval: Whole products such as valves, boilers & showers undergo mechanical and water quality testing. This type of approval demonstrates full compliance with requirements of the regulations and byelaws, provided the fitting is installed according to any conditions given with the approval.

WRAS Material Approval: Non-metallic materials & components, such as rubber sheet material & ‘O’ rings, undergo testing only for their effects on water quality. This type of approval demonstrates that the non-metallic material/component does not itself contaminate the water and therefore satisfies this particular requirement of regulations and byelaws.

Where do the regulations apply?

The Regulations are typically in effect between the boundary of a property and the point of discharge as illustrated below.

Source: WRAS What is a WRAS Approval?

Source2 : WIKI

Unless the code governing what you do dis-allows it, or the requirement is for seamless pipe only, the two are interchangeable.

As an example, the company I work for is a distributor of steel pipe, flanges and fittings. When we order pipe of this type, we order it “quad stencilled”, which means it complies with and is certified to all of the following:

A/SA 53B

A/SA106B

API5L B

CSA Z245.1 Grade 290 cat I

Because these standards are so similar, it is easy to make one piece of pipe that will satisfy the requirements of all. It is far more efficient for us to do this than carry seperate inventories of each A53B, A106B, API 5L B and CSA.

A couple of notes to go with this.

A106-B pipe is, be definition, seamless, whereas, A53-B, API 5L -B and CSA can be either seamless OR welded. So, when we order quad stencilled pipe, is has to be seamless. Also, the spec for CSA is higher than for the ASTM/ASME and API grades, but CSA is a requirement for a number of our customers, which is why we add that on.

Duplex stainless steels are becoming more common. They are being offered by all the major stainless steel mills for a number of reasons:

- Higher strength leading to weight saving

- Greater corrosion resistance particularly stress corrosion cracking

- Better price stability

- Lower price

There is a conference on the subject of duplex every 2-3 years where dozens of highly technical papers are presented. There is a lot of marketing activity surrounding these grades. New grades are being announced frequently.

Yet, even with all this interest, the best estimates for global market share for duplex are between 1 and 3%. The purpose of this article is to provide a straightforward guide to this steel type. The advantages and disadvantages will be described.

Principle of Duplex Stainless Steels

The idea of duplex stainless steels dates back to the 1920s with the first cast being made at Avesta in Sweden in 1930. However, it is only in the last 30 years that duplex steels have begun to “take off” in a significant way. This is mainly due to advances in steelmaking techniques particularly with respect to control of nitrogen content.

The standard austenitic steels like 304 (1.4301) and ferritic steels like 430 are relatively easy to make and to fabricate. As their names imply, they consist mainly of one phase, austenite or ferrite. Although these types are fine for a wide range of applications, there are some important technical weaknesses in both types:

Austenitic – low strength (200 MPa 0.2% PS in solution annealed condition), low resistance to stress corrosion cracking

Ferritic – low strength (a bit higher than austenitic, 250 MPa 0.2% PS), poor weldability in thick sections, poor low temperature toughness

In addition, the high nickel content of the austenitic types leads to price volatility which is unwelcome to many end users.

The basic idea of duplex is to produce a chemical composition that leads to an approximately equal mixture of ferrite and austenite. This balance of phases provides the following:

- Higher strength – The range of 0.2% PS for the current duplex grades is from 400 – 550 MPa. This can lead to reduced section thicknesses and therefore to reduced weight. This advantage is particularly significant for applications such as:

o Pressure Vessels and Storage Tanks

o Structural Applications e.g. bridges- Good weldability in thick sections – Not as straightforward as austenitics but much better than ferritics.

- Good toughness – Much better than ferritics particularly at low temperature, typically down to minus 50 deg C, stretching to minus 80 deg C.

- Resistance to stress corrosion cracking – Standard austenitic steels are particularly prone to this type of corrosion. The kind of applications where this advantage is important include:

o Hot water tanks

o Brewing tanks

o Process plant

o Swimming pool structuresHow the Austenite/Ferrite Balance is Achieved

To understand how duplex steels work, first compare the composition of two familiar steels austenitic 304 (1.4301) and ferritic 430 (1.4016).

Structure Grade EN Number C Si Mn P S N Cr Ni Mo Ferritic 430 1.4016 0.08 1.00 1.00 0.040 0.015 – 16.0/18.0 – – Austenitic 304 1.4301 0.07 1.00 2.00 0.045 0.015 0.11 17.5/19.5 8.0/10.5 – The important elements in stainless steels can be classified into ferritisers and austenitisers. Each element favours one structure or the other:

Ferritisers – Cr (chromium), Si (silicon), Mo (molybdenum), W (tungsten), Ti (titanium), Nb (niobium)

Austenitisers – C (carbon), Ni (nickel), Mn (manganese), N (nitrogen), Cu (copper)

Grade 430 has a predominance of ferritisers and so is ferritic in structure. Grade 304 becomes austenitic mainly through the use of about 8% nickel. To arrive at a duplex structure with about 50% of each phase, there has to be a balance between the austenitisers and the ferritisers. This explains why the nickel content of duplex steels is generally lower than for austenitics.

Here are some typical compositions of duplex stainless steels:

Grade EN No/UNS Type Approx Composition

Cr Ni Mo N Mn W Cu 2101 LDX 1.4162/

S32101Lean 21.5 1.5 0.3 0.22 5 – – DX2202 1.4062/ S32202 Lean 23 2.5 0.3 0.2 1.5 – – RDN 903 1.4482/

S32001Lean 20 1.8 0.2 0.11 4.2 – – 2304 1.4362/

S32304Lean 23 4.8 0.3 0.10 – – – 2205 1.4462/

S31803/

S32205Standard 22 5.7 3.1 0.17 – – – 2507 1.4410/

S32750Super 25 7 4 0.27 – – – Zeron 100 1.4501/

S32760Super 25 7 3.2 0.25 – 0.7 0.7 Ferrinox

255/

Uranus 2507Cu1.4507/

S32520/

S32550Super 25 6.5 3.5 0.25 – – 1.5 In some of the recently developed grades, nitrogen and manganese are used together to bring the nickel content to very low levels. This has a beneficial effect on price stability.

At present, we are still very much in the development phase of duplex steels. Therefore, each mill is promoting its own particular brand. It is generally agreed that there are too many grades. However, this is likely to continue until the “winners” emerge.

Corrosion Resistance of Duplex Steels

The range of duplex steels allows them to be matched for corrosion resistance with the austenitic and ferritic steel grades. There is no single measure of corrosion resistance. However, it is convenient to use the Pitting Resistance Equivalent Number (PREN) as a means of ranking the grades.

PREN = %Cr + 3.3 x %Mo + 16 x %N

The following table shows how the duplex steels compare with some austenitic and ferritic grades.

Grade EN No/UNS Type Typical PREN 430 1.4016/

S43000Ferritic 18 304 1.4301/

S30400Austenitic 19 441 1.4509/

S43932Ferritic 19 RDN 903 1.4482/

S32001Duplex 22 316 1.4401/

S31600Austenitic 24 444 1.4521/

S44400Ferritic 24

316L 2.5 Mo 1.4435 Austenitic 26 2101 LDX 1.4162/

S32101Duplex 26 2304 1.4362/

S32304Duplex 26 DX2202 1.4062/ S32202 Duplex 27

904L 1.4539/

N08904Austenitic 34 2205 1.4462/

S31803/

S32205Duplex 35 Zeron 100 1.4501/

S32760Duplex 41 Ferrinox 255/

Uranus 2507Cu1.4507/

S32520/

S32550Duplex 41 2507 1.4410/

S32750Duplex 43 6% Mo 1.4547/

S31254Austenitic 44 It must be emphasised that this table is only a guide to material selection. It is always important to assess the suitability of a particular with a full knowledge of the corrosive environment.

Stress Corrosion Cracking (SCC)

SCC is a form of corrosion which occurs with a particular combination of factors:

- Tensile stress

- Corrosive environment

- Sufficiently high temperature. Normally 50 deg C but can occur at lower temperatures around 25 deg C in specific environments, notably swimming pools.

Unfortunately, the standard austenitic steels like 304 (1.4301) and 316 (1.4401) are the most susceptible to SCC. The following materials are much less prone to SCC:

- Ferritic stainless steels

- Duplex stainless steels

- High nickel austenitic stainless steels

The resistance to SCC makes duplex steels suitable materials for many processes which operate at higher temperatures, notably:

- Hot water boilers

- Brewing tanks

- Desalination

Stainless steel structures in swimming pools are known to be prone to SCC. The use of standard austenitic stainless steels like 304 and 316 is forbidden in this application. The best steels to use for this purpose are the high nickel austenitic steels such as the 6% Mo grades. However, in some cases, duplex steels such as 2205 (1.4462) and the superduplex grades can be considered.

Barriers to Using Duplex Steels

The attractive combination of high strength, wide range of corrosion resistance, moderate weldability would seem to offer great potential for increasing the market share of duplex stainless steels. However, it is important to understand the limitations of duplex stainless steels and why they are always likely to be “niche players”.

The advantage of high strength immediately becomes a disadvantage when considering formability and machinability. The high strength also comes with lower ductility than austenitic grades. Therefore, any application requiring a high degree of formability, for example, a sink, is ruled out for duplex grades. Even when the ductility is adequate, higher forces are required to form the material, for example in tube bending. There is one exception to the normal rule of poorer machinability, grade 1.4162.

The metallurgy of duplex stainless steels is much more complex than for austenitic or ferritic steels. This is why 3 day conferences can be devoted just to duplex! This factor means that they are more difficult to produce at the mill and to fabricate.In addition to ferrite and austenite, duplex steels can also form a number of unwanted phases if the steel is not given the correct processing, notably in heat treatment. Two of the most important phases are illustrated in the diagram below:

Sigma phase 475 degree embrittlement Both of these phases lead to embrittlement, i.e. loss of impact toughness.

The formation of sigma phase is most likely to occur when the cooling rate during manufacture or welding is not fast enough. The more highly alloyed the steel, the higher the probability of sigma phase formation. Therefore, superduplex steels are most prone to this problem.

475 degree embrittlement is due to the formation of a phase called α′ (alpha prime). Although the worst temperature is 475 deg C, it can still form at temperatures as low as 300 deg C. This leads to a limitation on the maximum service temperature for duplex steels. This restriction reduces the potential range of applications even further.

At the other end of the scale, there is a restriction on the low temperature use of duplex stainless steels compared to austenitic grades. Unlike austenitic steels duplex steels exhibit a ductile-brittle transition in the impact test. A typical test temperature is minus 46 deg C for offshore oil and gas applications. Minus 80 deg C is the lowest temperature that is normally encountered for duplex steels.

Going Further with Duplex Stainless Steels

More detailed information on duplex can be found in:Practical Guidelines for the Fabrication of Duplex Stainless Steels

Summary of Duplex Characteristics

- Twice design strength of austenitic and ferritic stainless steels

- Wide range of corrosion resistance to match application

- Good toughness down to minus 80 deg C but not genuine cryogenic applications

- Particular resistance to stress corrosion cracking

- Weldable with care in thick sections

- More difficult to form and machine than austenitics

- Restricted to 300 deg C maximum

Source: Article: Duplex Stainless Steels – A Simplified Guide

Static electricity is experienced during seasons when the air is dry. The crackle sound that occurs when removing a sweater is from the static electricity generated by friction between clothing materials. Similarly, the slight pain sensation experienced when touching a door knob after walking on carpet is due to the static electricity, which was built up in the body from rubbing the carpet, being discharged across the small gap between the door knob and your hand.

Such experiences with static electricity can be relatively common occurrences, so we often don’t pay much attention to them in our daily lives.However, static electricity can be a big problem for electronic parts. At a few kilovolts, our bodies only experience a slight pain sensation (assuming a very slight current level), but some electronic parts can be ruined by only 0.1 kV.

Countermeasures for static electricity are included in the analytical instruments themselves, but larger amounts of static electricity could cause them to malfunction.Furthermore, some laboratory instruments, such as HPLC (high performance liquid chromatograph) systems, which use flammable organic solvents, require being especially careful due to the risk of fire.

In addition, because it is difficult to understand the mechanism of how static electricity accidents occur, and because some aspects that lead to static electricity accidents only occur when several factors coincide, caution is often ignored. Nevertheless, particular caution is especially required when using large amounts of solvent, because if an accident does occur, it can cause a great deal of damage.This page specifically describes HPLC effluents flowing into liquid waste containers, but the danger also applies to non-HPLC situations where a solvent with low conductivity flows into a container with low conductivity.

• The Possibility of Accidents from Static Electricity Generated by Flowing Liquid

Static electricity generated near the HPLC outflow into a liquid waste container could potentially cause an accident. The process is described below.

1. Generation of Static Electricity

When liquid is passed through thin tubing at a high flowrate, as it is in HPLC systems, the electrostatic charge of the flowing matter generates static electricity (flow electrification). (The charge level is higher for poorly conductive solvents flowing through plastic tubes. In addition, large amounts of air bubbles flowing through the tube can amplify the static electricity.A: Charge that moves along with liquid flow

B: Charge that is fixed to a solid surface and cannot move

Generation of Static Electricity by a Liquid Flowing over a Solid

2. Accumulation of Static Electric Charge

If electrostatically charged liquid accumulates in an electrically insulated container, the amount of charge gradually increases to a point where it can easily generate high voltages, on the order of several kV.3. Release of Energy Through Electrical Discharge

If an electrical conductor comes within a certain distance of the container, an electrical discharge occurs, which releases thermal energy.4. Ignition of Flammable Substances

If there is a sufficient concentration of flammable gas in the surrounding atmosphere, the gas is more easily ignited.Figure 2 illustrates potential accident situations.

Situations with Danger of a Static Electricity Accident

Intake of Air Bubbles Increases Static Electricity

• Preventing Static-Electricity Accidents

To prevent static electricity accidents, measures should focus on preventing the generation and accumulation of static electricity. In addition, to further ensure that accidents are prevented, it is important to implement multiple prevention measures simultaneously. In particular, the following measures should be taken if large amounts of flammable solvents are used.

Measure 1

Use a metal liquid waste container (with a conductive interior surface, such as a plated metal can) and connect the container to ground.

Properly ground liquid waste containers. There is no point in using a metal container if it is not grounded or the ground wire becomes disconnected. (P/N 228-21353-91 can also be used as a ground wire.) This ensures that static charge does not accumulate in the waste liquid or the container.

Even some metal containers have surfaces that are oxide-coated or laminated and, therefore, may not be conductive. Use an electrical tester to confirm that the container is grounded. If only liquid with a very low conductivity (10-10 S/m or less) is discharged into the waste container, one method is to add a safe conductive liquid to the container.

Configuration with Measures to Prevent Static Electricity Implemented

Measure 2

To prevent sparks from entering the waste container, keep the size of any gaps at inlet and outlet openings as small as possible.

(To minimize such gaps, P/N 228-21354-91 caps can also be used for 18 L and 4 L cans.)Measure 3

Keep electrostatically charged objects, including human bodies, away from the waste container.

To prevent the body from becoming charged, wear anti-static clothing or shoes, ground the body using an anti-static wrist strap (with a 1 MΩ resistor to protect the body), or provide conductive floor surfaces in work areas, such as with anti-static floor mats. If you have not taken any anti-static measures, touch a grounded metal object before approaching the waste container in order to ground any electrostatic charge from your body.Measure 4

Use tubing with a larger inner diameter (at least 2 mm, for example) for drain lines through which large amounts of liquid flow.

Air bubbles in the liquid can increase electrostatic charge by a factor of several tens. Check the tubing connections for air leaks.Measure 5

If the liquid waste container cannot be made conductive, make sure the end of the drain tube remains below the surface of the liquid in the waste container. Alternatively, place grounded metal in the liquid.

However, this method is mostly ineffective for liquids with low conductivity (10-10 S/m or less).Measure 6

Use a liquid waste container that is as small as possible to minimize the damage in the event of a fire.Measure 7

Increasing the humidity level (above 65 %, for example) can have an anti-static effect. Therefore, do not let the room become dry.Static electricity accidents can be prevented by observing the measures indicated above. These measures may seem like an unnecessary bother, but being prepared for such possibilities is also important.

As a manufacturer of HPLC systems, we hope to supply easy-to-use peripheral products that are carefully designed for safety as well.1.Flammables: Laboratories contain many flammable substances, such as organic solvents. Keep flammable substances covered to prevent exposure. Provide ventilation for flammable vapors. (Select the height of ventilation fans based on most solvents being heavier than air, but hydrogen being lighter than air).

2.Electrical System: Circuit boards are especially vulnerable to static electricity. In particular, if a statically charged person touches an electrical device with a metal tool, it can cause a malfunction or an instantaneous power interruption. Form a habit of touching the building or water pipes to eliminate any static charge before touching an electrical device.

3.Powders: Powders can cling or jump about due to static from friction with the container or from taking on the static charge from humans. When weighing powders, an ionizer can be used to eliminate static electricity.

Source: Beware of Static Electricity Generated by Flowing Liquids : SHIMADZU (Shimadzu Corporation)

Stellite alloys are a group or a range of cobalt-chromium alloys. They are designed to be resistant to wear and corrosion. These alloys may also have some portions of tungsten or molybdenum and some small but critical amounts of carbon. Stellite is a trademarked name of Deloro Stellite Company supplying Stellite alloys like Stellite3, Stellite 6, Stellite 12 and Stellite 21. Deloro Stellite Company also supplies other products like casting, machinery, welding, coating, knives and many others. The alloy was invented in the early 1900s by American metallurgist Elwood Haynes as a proper substitute for easily staining silverware.

The CAS Registry Number for Stellite alloys is 12638-07-2.

There are many types of Stellite alloys composed of varying quantities of cobalt, chromium, molybdenum, tungsten, iron, nickel, boron, aluminum, carbon, manganese, phosphorus, silicon, titanium and sulfur in different proportions. Most Stellite alloy compositions contain at least four to six of the listed elements.

Stellite alloys do not have any specific chemical formula as various types of alloys are formed by combining a number of elements in different proportions. The various types of Stellite alloys are represented by using numbers, such as Stellite 1, Stellite 6K and Stellite 706.

A special form of Stellite known as Talonite is manufactured by hot-rolling and hardening a specific alloy combination. Talonite combines the properties of hardness, machinability and wear resistance. It is important to note that not all types of Stellite alloys can be processed to create Talonite.

Stellite alloys are non-magnetic alloys which are highly resistant to corrosion. A range of different alloy compositions are prepared by combining different elements in varying proportions and the properties of an individual alloy composition might vary from an alloy of a different composition. Different alloy compositions are used for different purposes and valued for their functional flexibility. The alloy Stellite 100 is mostly used nowadays for cutting tools as it is very hard and is capable of maintaining a great cutting edge even when exposed to high temperatures. The alloy is also resistant to processes such as hardening and annealing that might result from excessive heat. Other Stellite alloys are manufactured to combine the properties of corrosion resistance, wear resistance and the ability to tolerate extreme temperatures.

Stellite alloys can be characterized as having great hardness and toughness. They are also normally highly resistant to corrosion. The extreme harness of these alloys frequently makes it difficult to work with them and so anything made from these alloys are normally very expensive. Usually, Stellite parts are precisely cast to avoid any need of further excessive machining. Stellite alloys are more frequently machined by grinding instead of cutting. These alloys usually have very high melting points resulting from the combined content of cobalt and chromium.

The various uses of Stellite alloys are discussed below:

Stellite alloys are normally very stable materials. However, they can react with oxidizing agents and mineral acids to form explosive hydrogen gas which can cause fire hazards.

Under normal circumstances, handling of Stellite alloys hardly poses any risk of health hazards. However, machining or welding with these alloys can produce dust, fumes and small particles of component alloy elements. These particles can pose a serious threat to human health when they enter the body in excess of maximum exposure limits.

Inhalation: Inhaling particles of Stellite alloy generated from grinding, welding or similar processes can cause asthma and metal flume fever. Component materials like boron, chromium, cobalt, copper, manganese, molybdenum, nickel and vanadium are respiratory irritants.

Ingestion: Stellite particles normally do not enter the human body through ingestion. However in some cases a person’s hands, clothing or foods and drinks can get contaminated with dusts from Stellite alloy materials and the particles may enter the body through activities such as smoking, eating, drinking and nail biting. Ingesting Stellite particles can cause vomiting, diarrhea, nausea and abdominal pain.

Skin: Irritation, sensitization or allergic dermatitis can occur from the some of the components of Stellite alloys. When the skin comes in contact with vanadium, copper and nickel, it may result in dermatitis. Exposure of the skin to cobalt might cause allergic skin reactions and dermatitis. Skin exposed to manganese might suffer from excessive sweating. Vanadium and boron exposure causes skin irritation.

Eyes: If the eyes get contaminated by coming in contact with soiled fingers or airborne particles, it might result in irritation or abrasion of the eyes. Particles of Stellite materials can cause irritation of the eyes resulting from mechanical abrasion. Severe allergic conjunctivitis and eye irritation might result when dusts of cobalt enter the eyes. Irritation may also be caused by dusts of copper.

Chronic health effects resulting from Stellite alloys are difficult to detect as these alloys are made up of several elements. Effects of chronic inhalation include pulmonary fibrosis, chronic obstructive lung disease, rhinitis and bronchitis. Chronic occupational exposure to dusts of cobalt results in goiter, bloody urine and polycythemia.

Some elements of Stellite alloys have been recognized as carcinogenic substances by The International Agency for Research on Cancer (IARC). Exposure to nickel and nickel compounds, cobalt and cobalt compounds and hexavalent chromium can greatly increase the risk of cancer among workers dealing with these alloys.

Individuals already having sensitivity to certain elements and are prone to develop allergic reactions to metals like nickel, copper, chrome and cobalt might possibly encounter dermatitis and skin rashes. Persons already suffering from impaired pulmonary function can develop airway diseases and health conditions such as emphysema, asthma and chronic bronchitis, etc. when excessive concentrations of alloy fumes or dusts are inhaled. If any of these health conditions are already present, the inhalation of Stellite alloy particles can aggravate the symptoms. If a person is already suffering from prior damages to the Circulatory, Neurologic (nervous), Renal (kidney) or Hematogic (blood) systems, proper examinations or screening should be conducted for appropriate diagnosis of these patients. They should also be prohibited from entering areas contaminated by dusts of Stellite alloys.

Ventilation: The area should be well ventilated to minimize contamination of dust, fume and particles. Air exposure of materials should be kept below the recommended limits of exposure.

Respiratory: If the room is not properly ventilated and the exposure levels of alloy dust is not maintained below the exposure limits, adequate respiratory protection needs to be used by the working personnel. The respirators should be NIOSH-approved and have a proper air purifying filter.

Skin: Rubber or leather gloves should be used while dealing with Stellite alloys to avoid skin contact and for preventing metal abrasions and cuts. Unnecessary and risky skin contact can be easily avoided by using protective coveralls.

Eye: Safety goggles or glasses should be worn while entering a contaminated area.

Inhalation: The victim suffering from breathing difficulty due to inhalation of dust particles and fumes should be removed to an area of fresh air. A physician needs to be consulted if the breathing still does not improve.

Ingestion: The victim should drink plenty of water and try to vomit. A doctor should be consulted for ensuring further safety.

Skin: The infected area should be washed nicely with plenty of water. The victim should take a shower if possible. Contaminated clothing should be removed. Medical attention is required if irritation of skin persists.

Eye: The eyes should be washed well with ample amounts of water. A doctor needs to be consulted if eye irritation persists. While working with powders and dusts of Stellite alloys, a person should not wear contact lenses.

Environmental Surveillance: Air samples should be taken from the industrial working area for regularly checking the levels of air contamination.

Medical Surveillance: The workers should regularly go through a thorough health check up. Tests like chest x-rays, lung tests and routine physical examinations should be conducted on regular intervals to ensure safety of the workers.

Waste Disposal: Wastes of Stellite alloys should be disposed of by following the relevant Local, Provincial and Federal regulations regarding waste management.

Stellite alloys should not be used in nuclear power plants as cobalt can be changed to Cobalt-60 in nuclear reactors, which is a harmful radioisotope having a half life of five years and releases strong gamma radiation.

Stellite alloys are often a first choice in many industrial applications and functions. They are highly valued for their high resistivity to corrosion and weariness and hardness.

It is maximum allowable torque a stem of a quarter turn valve can be subjected to without mechanical failure. Engineering unit Nm OR lb-in

During valve operation, torque delivered by actuator (Pneumatic or electric) at any stage, should not exceed MAST value. If it happens stem may be subjected to mechanical failure.

In some projects it has happened that MAST value calculated by valve vendor was higher than actual, even than it resulted in failure of stem.

follow main source

Source: Maximum Allowable Stem Torque (MAST)

Source: MAST Calculation

Below link is given for source of data, If you any issue please contact

Trim is composed of stem, seat surfaces, back seat bushing and other small internal parts that normally contact the surface fluid.

Source: Piping Design Engineer Interview Questions (Part-1) | Oil And Gas Club

Design acc.to API 6D, DIN3357Face-to-Face acc. to ASME B16.10Flange acc. to ASME B16.5, DIN EN1092Butt Weld acc. to ASME B16.25Test acc. to API 598, DIN3230Fire Proof acc. to API607Anti-H2S acc. to NACE MR-0175Size from 2” to 42”,Pressure from 150LB to 2500LB,PN16 to PN320We cover the following range of exotic alloys for our valve body and trims:Duplex and Super Duplex grades: 318LN, A182 F51, A182 F55, A479 F51, A995 4A, A995 Gr. 5A, A995 Gr. 6A, A890 Gr. 4A, A890Gr. 5A CEMN, A890Gr. 6A CD3MWCUN, A479 F55, UNS S31803, UNS S32205, UNS S32750, UNS S32760, X2CrNiMoN22-5-3, X2CrNiMoCuWN25.7.4, 1.4410, 1.4501, 1.4507, 1.4462, Ferralium 255, Uranus 45N®, Uranus 52N®.Titanium grades: Titanium Gr.2, Titanium Gr.3, Titanium Gr.5, T40, T60, TA6V, Ti6Al4V, UNS R50400, UNS R50550, UNS R56400, 3.7034, 3.7035, 3.7164, 3.7165, A182 316Ti.Zirconium – Zr: Zr 702, Zr 705, UNS R60702, UNS R60705.Uranus B6 grades: 904L, UNS N08904, 1.4539, X1NiCrMoCuN25-20-5, Uranus B6®.Tantalum – Ta grades: Ta, Ta pur ( 99.85 % min), Ta-2, 5%W (KBI 6) ;Ta-10%W (KBI 10).Nickel grades: Nickel 200, Nickel 201, UNS N02200, UNS N02200, 2.4060, 2.4061, 2.4066, 2.4068.Hastelloy® grades: HASTELLOY® B-2 alloy, HASTELLOY® B-3 alloy, HASTELLOY® C-22 alloy, HASTELLOY® C-276 alloy, HASTELLOY® C-4 alloy, UNS N10665, UNS N10675, UNS N06022, UNS N10276, UNS N06455, 2.4617, 2.4600, 2.4602, 2.4819, 2.4610, A494 CW12MW.Inconel and Incoloy grades: INCONEL® 600, INCONEL® 601, INCONEL® 617, INCONEL® 625, INCONEL® 718, INCONEL® 725, Inconel A494-CY40, INCOLOY® 800, INCOLOY® 800H, 800HT, UNS N06600, UNS N06601, UNS N06617, UNS N06625, UNS N07718, UNS N07725, UNS N08810, UNS N08811, 2.4816, 2.4851, 2.4663, 2.4856, 2.4668, 1.4876, 1.4958, 1.4959.Monel grades: MONEL® 400, MONEL® K500, UNS N04400, UNS NO5500, 2.4360, 2.4361, 2.4375.Alloy 20 grades: Alloy 20, Carpenter 20, A351 CN7M, A20 UNS 08020.High temperature and other exotic alloys: A182 F5, A182 F22, A216 WC6, A216 WC9, A182 F61, A182 F91, A182 F321, A182 F347, A182 F347H, A182 F44, 254 SMO, 6moly, 6mo, Avesta 904L, A217 C5, A182 F11, A351 CG8M, Aluminium Bronze Valve.Features:1.Blow-out proof stemFor the purpose of preventing the stem from flying off resulting in abnormal rising of the inner pressure of valve,shoulder is fixed at the lower part of the stem.In addition,in order to prevent leakage resulting from burnout of packing set of the stem in a fire,thrust bearing is set at the contact position of the shoulder at lower part of the stem and valve body.Thus an inverse seal seat is formed which will prevent leakage and avoid accident.2.Key lockLocks can be used to lock the manual valve when it is fully open or closed so as to prevent non-working personnel from pulling the handle which may result in misoperation of valve.It can also avoid opening or closing of valve resulting from the shock from pipelines or unpredictable factors that may cause an accident.For working pipelines such as combustible and explosive oil,gas and chemical medium,or for field piping site,the locking mechanism is especially useful.3.Anti-fire safe designWhen the trunnion ball valve be used normally,its sealed by seat and ball surface,seat retainer sealed by O-ring and body,this is soft sealed and reliable sealing.When the seat and O-ring are burnt,the seat retainer and body will be sealed by expanded graphite.Thus act anti-fire safe purpose. 4.Anti-static deviceIn order to prevent friction among ball,stem and PTFE that generates static electricity which may light the combustibles and explosives that cause an accident,in this ball valve,static-conduction spring is set between the stem and the ball,the stem and the body.Thus static electricity is conducted to ground and system safety is secured.5.Free leakage of body Sealed constructionThe connective position of valve body and bonnet is double sealed by gasket and O-ring,on this base,such factors as fire,high temperature,shock and uneven opening or closing of the torque all can not induce external leakage.6. Double block&bleed(DBB)When ball is full open or close position,the transmitter substance in center cavity of body can be released by drainage and emptying devices.In addition,the over loaded pressure in the center cavity of valve can be released to low pressure end by self relief seat.7.Emergency sealingCompound injection holes are designed and compound injection valves are installed at locations of stem/cap and body support of side valve.When sealing of stem or seat is damaged to induce leakage,the compound can be used to do the second time sealing.A concealed check valve is installed in side of each compound injection valve to prevent compound from out flowing due to the action of transmitter substance.The top of the compound injection valve is the connector for fast connection with compound injection gun.8.Automatic body cavity reliefWhen the body pressure going up un-normally as the unstable factor,the trunnion ball valve downstream seat will be pushed by unnormal pressure,and

Source: Trunnion Mounted Duplex and Super Duplex Ball Valve,

cryogenic valves, please consider following points:-

- Body(Austenitic SS) and trim material selection(Austenitic SS)

- Soft seat(PCTFE) and seal(Lip seals-PTFE+SS/Elgiloy) material for the ball valves.

- Material of seal ring(Solid seal ring is generally selected) for triple offset butterfly valves

- Extended Bonnet requirement for the valves to protect the valve packing from freezing. Extended bonnet length in accordance with BS 6364/MSS SP-134/ ISO 28921/Shell SPE 77/200.

- Cryogenic testing in accordance with standards/client documents stated in point no. 4 above.

- Cavity relief mechanism for valves with inherent cavity. This is a common requirement for valves with flashing service. Triple offset butterfly and Eccentric ball valve are cavity free.

These are some of the main requirements.- The purpose of extended bonnet is to provide a insulating vapor column and to protect the packing from cryogenic temperatures. at cryogenic temperatures, the graphite packing will freeze and will render the valve in operable. So, extended stem is not a alternative to extended bonnet. So, for cryogenic valves, we have to provide extended bonnet only

Source: Linkedin-Cryogenic service